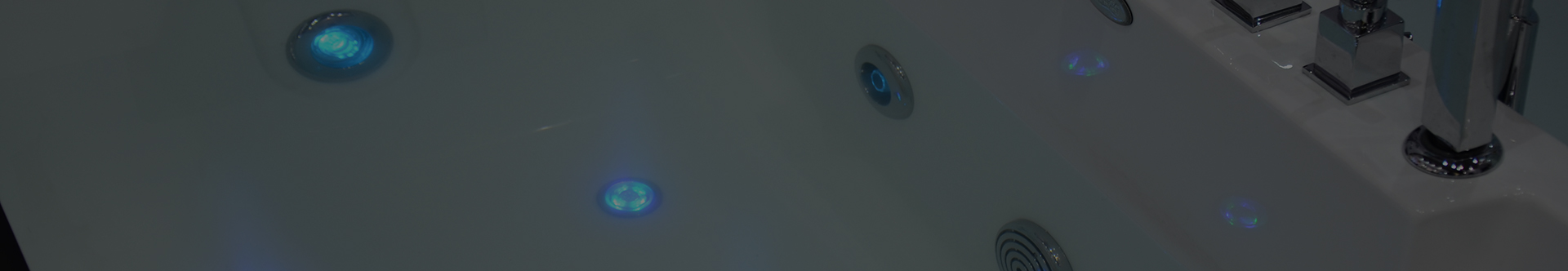

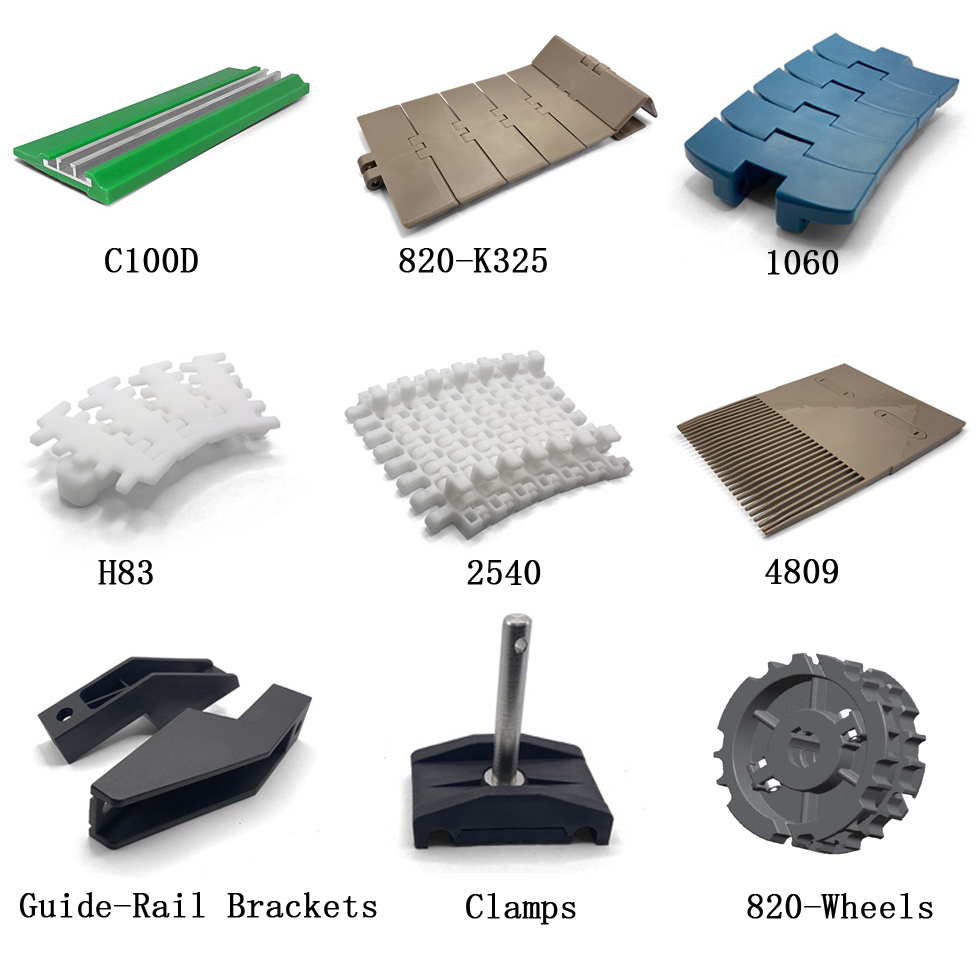

Jetway flat top OPB conveyor belt

Product Display

Quick Details

1.Luohe Global modular conveyor belt has more than 10 times service life,long life time and reducing replacement cost than traditional conveyor belt.

Applications

FAQ

1. Q:Are you a factory outlets or trading company?

A:We are a factory outlets.

2. Q:If small order is acceptable? Yes,trial order is welcome!

A:Yes,trial order is welcome!

3. Q:Could you offer us samples?

A:Yes, generally, free sample for 1~2pcs, and the freigt you need to bear.

4. Q:What’s your shipment terms?

A:Generally, if samples, by air or by express; If bigger order by sea.

5. Q:Could you put our logo on the packing?

A:Yes, it is easy to print your logo on the packing.

6. Q:What’s your package?

A:In standard export cartons, but could be designed as your request.

7. Q:What’s your main port of lading?

A:FoShan/GuangZhou/ShenZhen/ShangHai/NingBo.

Packaging and Shipping

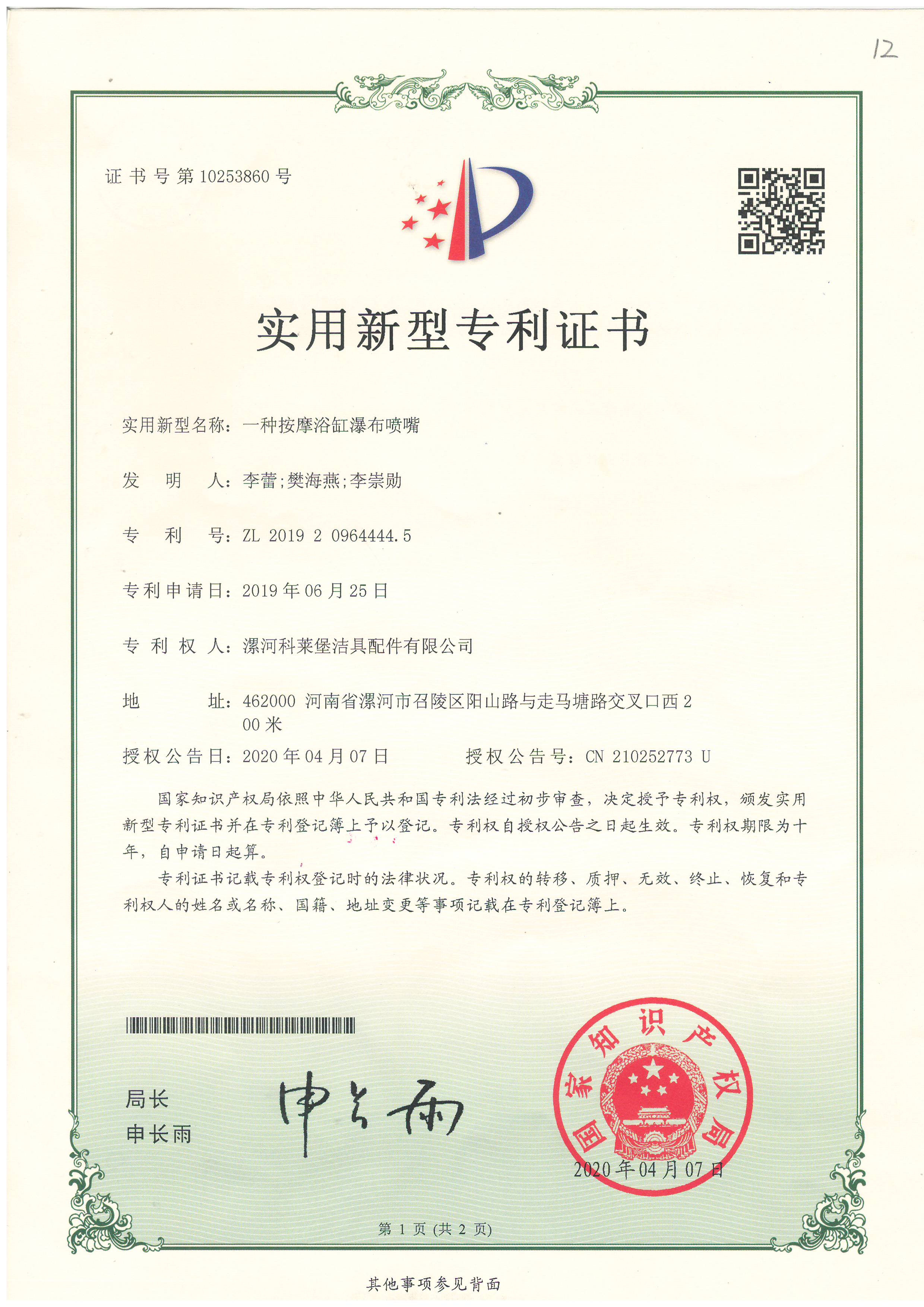

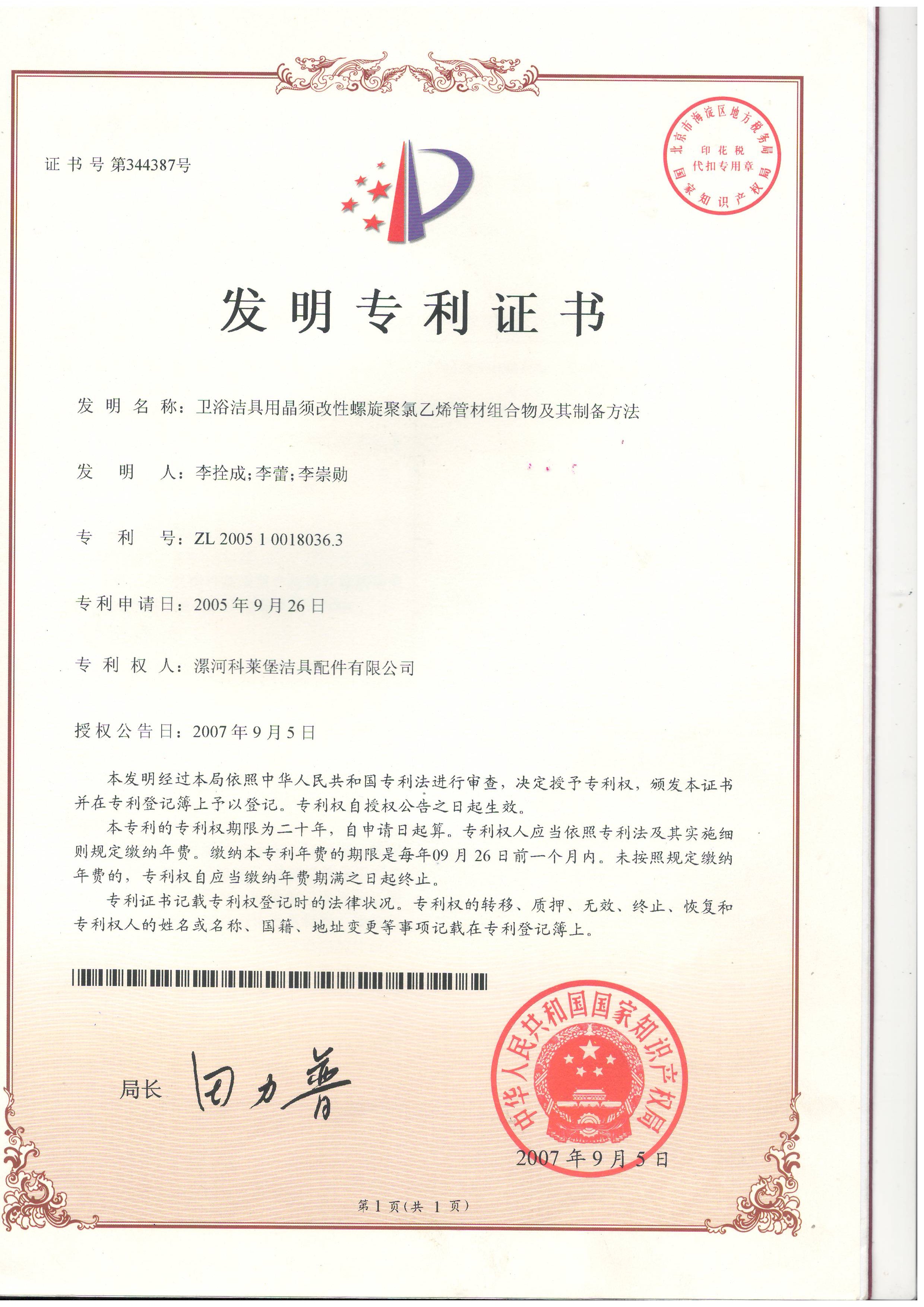

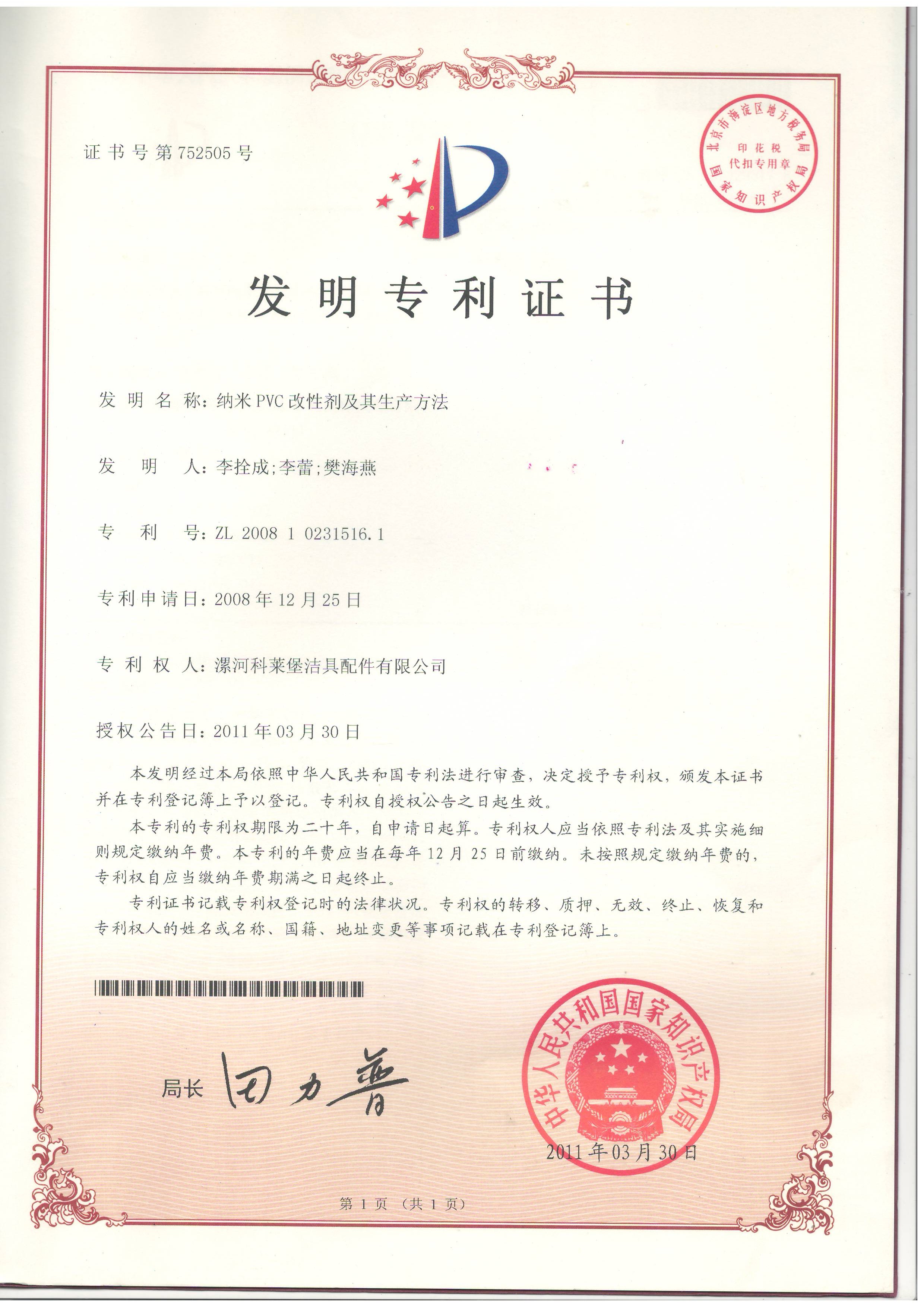

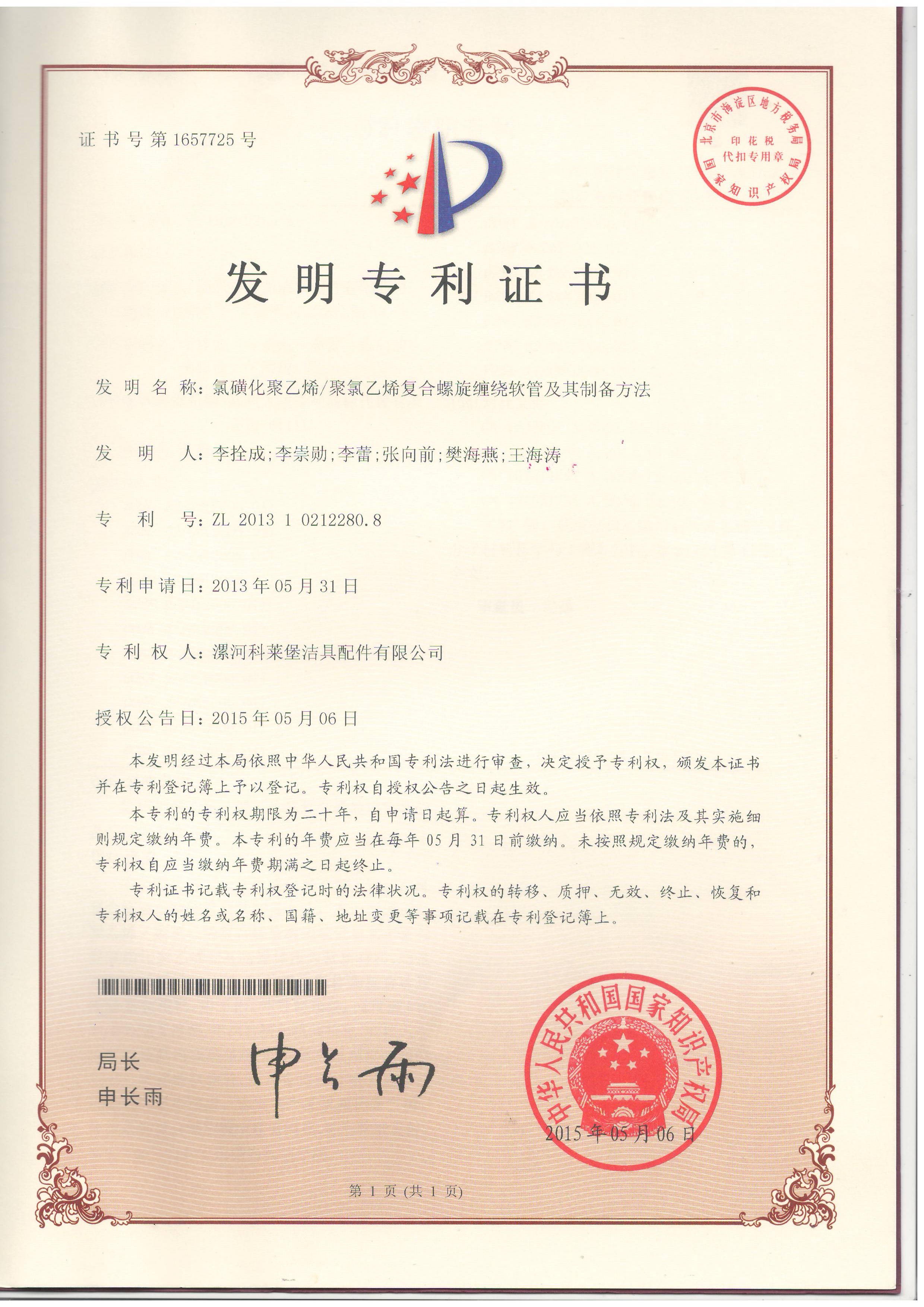

Certificates

1.png)

3-213x300.png)

1.png)

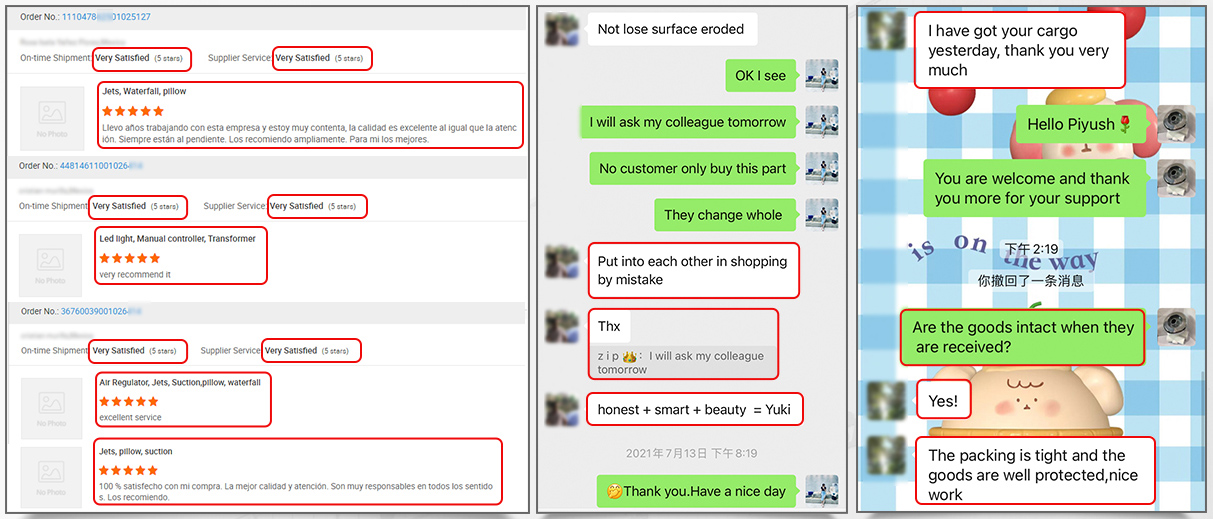

Customer Feedback

Photos of Exhibition Customers Collection

Welcome to Visit Our Factory

News

Plastic conveyor belt from Luohe Global Technology Co.,Ltd

our company Luohe Global Technology Co.,Ltd is dedicated in conveyor belts and conveyor components for 17 years. With SGS certificate,accept OEM and ODM.

1. What are plastic conveyor belt?

plastic conveyor belt is a part of conveyor machine, which is composed of power device (motor), transmission shaft, roller, tensioning device, chain wheel, chain, bearing, lubricant, chain plate, etc. the main two parts driving the transportation of objects are: chain, which uses its cyclic motion to provide traction power; The plastic conveyor belt is used as the carrier in the conveying process.

Material of plastic conveyor belt:it is made by POM material mainly,but also can make by PP material.POM material is expensive than pp,and it is more hard.pom material can not use in the industry which products with strong acidity and alkalinity,

Size of plastic conveyor belt:it can be customized,or choose from the exist size,the size will depends on the conveyor machine you used.

Scope of application of plastic conveyor belt:It is widely used for automatic transportation, distribution of food, canned food, medicine, beverage, cosmetics and washing products, paper products, condiments, dairy and tobacco, as well as the connecting transportation of subsequent packaging.

Characteristic of plastic conveyor belt:The conveying surface of the chain conveyor is flat and smooth, with small friction, and the transition of materials between the conveying lines is smooth. It can transport all kinds of glass bottles, PET bottles, pop cans and other materials, as well as all kinds of bags,

Chain plates are made of stainless steel and engineering plastics, with various specifications. They can be selected according to the requirements of materials and processes to meet the different needs of all walks of life,

Large transmission capacity, can bear large loads, such as electric vehicles, motorcycles, generators and other industries,

2. What are The Different Types Of plastic conveyor belt?

There are basically two big types for the plastic conveyor belt:table top plastic chain,modular conveyor belt,and some other kind belt like steel table top chains,multifelx chains,flexible chains,roller chains.

The conveying speed is accurate and stable to ensure accurate synchronous conveying,

Chain conveyor can be washed or immersed in water directly. The equipment is easy to clean and can meet the hygiene requirements of food and beverage industries,

Flexible layout. Horizontal, inclined and turning conveying can be completed in one conveying line,

Simple structure and convenient maintenance.

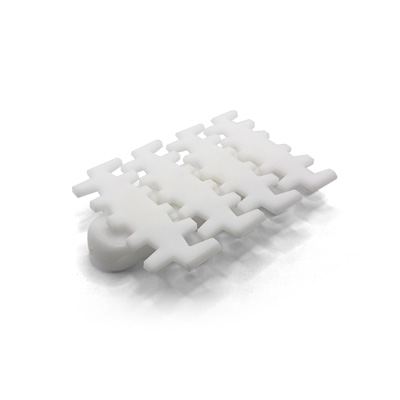

Table top plastic chains are made of engineering plastic and are connected using stainless steel pins,The plastic tabletop chains constitute a light-weight yet strong and silent alternative to steel chains.

These chanis are used mainly in the food and packaging industry for conveying many kinds of containers. For example: PET bottle,pet petaloid bottle,aluminum and steel can,cartons,trays,packaged products (cartons,shrink packs),glass,plastic containers.

Benefits:

-accuracy of molding process guarantees optimum flatness

-high wear resistance and low friction

-high working load

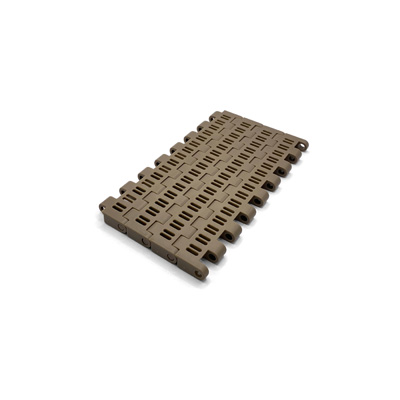

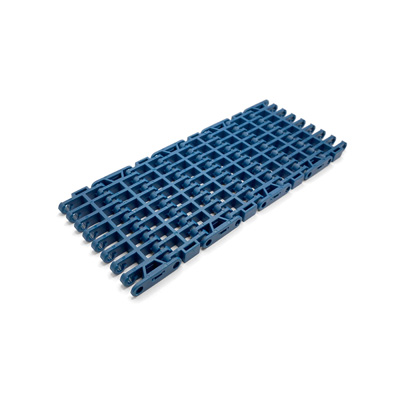

Modular Plastic Conveyor Belts are made with a series of several long, narrow modular plastic segments which are interlinked to form a continuous belt. Plastic’s durability over other belt materials also gives modular belts an edge over many alternatives in terms of load capacity, resistance to wear, and resilience in harsh environments.

If a modular belt is damaged it’s possible to replace only the broken plastic segments while leaving the bulk of the belt intact, thereby reducing repair costs and downtime. For applications where a rigorous standard of cleanliness or sterilization, like food processing or pharmaceuticals, plastic modular conveyors are more easily cleaned and sanitize than many alternatives, and are ideal for reducing the potential for standing liquid and bacteria retention.

Flat top:suitable for a wide range of products,when a fully closed belt surface is preferred.

Flush grid:commonly used in applications where drainage or airflow is desired.

Raised rib:recommended in applications where product stability over transfers is a concern.

Friction top:commonly employed on incline conveyors,where the elevation of product changes,friction top modular belts can be used up to an angle of 20 degrees,depending on the pack style and material.

Roller top:used in a variety of low-pressure accumulation applications.

Perforated flat top:used when air flow and water flow are critical but the percentage of belt open area must remain low.

Except the straight running plastic conveyor belt,side flexing plastic conveyor belt also widely offers a solution for almost any curved application.

Our flexible chains are capable of making sharp radius bends in either the horizontal or the vertical plains with very low friction and low noise.

Operating temperature:-20-+60℃

allowed max speed:50m/min

Applications:

Food and beverage(bottles and cans)

Toilet papers

Cosmetics

Tobacco manufacturing

Bearings

Mechanical parts

In actual use, the modular plastic conveyor belt is often slightly larger than the table top plastic conveyor belt, and the wear is relatively serious, so the modular plastic conveyor belt has become the weak point in the entire conveyor chain. Its damage forms are mainly severe wear, fracture and pulling, and the main causes are:

1. Long term pulsating load, fatigue failure;

2. The connecting pin or bolt is loose and falls off, and it is not found and supplemented in time, resulting in uneven force on the connecting link or pull;

3. For the vertical ring, the unilateral wear is more serious, and it is easy to break if it is not replaced in time;

4. After the chain is clamped, great dynamic load and impact load will be generated, which will cause the instantaneous huge fluctuation of the transmission chain's movement speed and make the transmission chain run unstably, thus accelerating the wear or fracture of the connecting link;

5. Poor manufacturing quality, poor wear resistance or toughness, and low hardness, or fatigue cracks caused by stress concentration, resulting in insufficient strength.

The damage of the connecting ring of the chain conveyor is roughly caused by the above five reasons, which requires the enterprise to regularly repair the equipment when using the chain conveyor, and immediately deal with the problems found.